IWST scientists are creating a material that mimics plastic but is biodegradable.

Imagine if you could dispose of your ‘use and throw’ plastic items and still not be worried about polluting the Earth. This is the proposition put forth by scientists at the Institute of Wood Science & Technology (IWST), who are working on making plastic biodegradable.

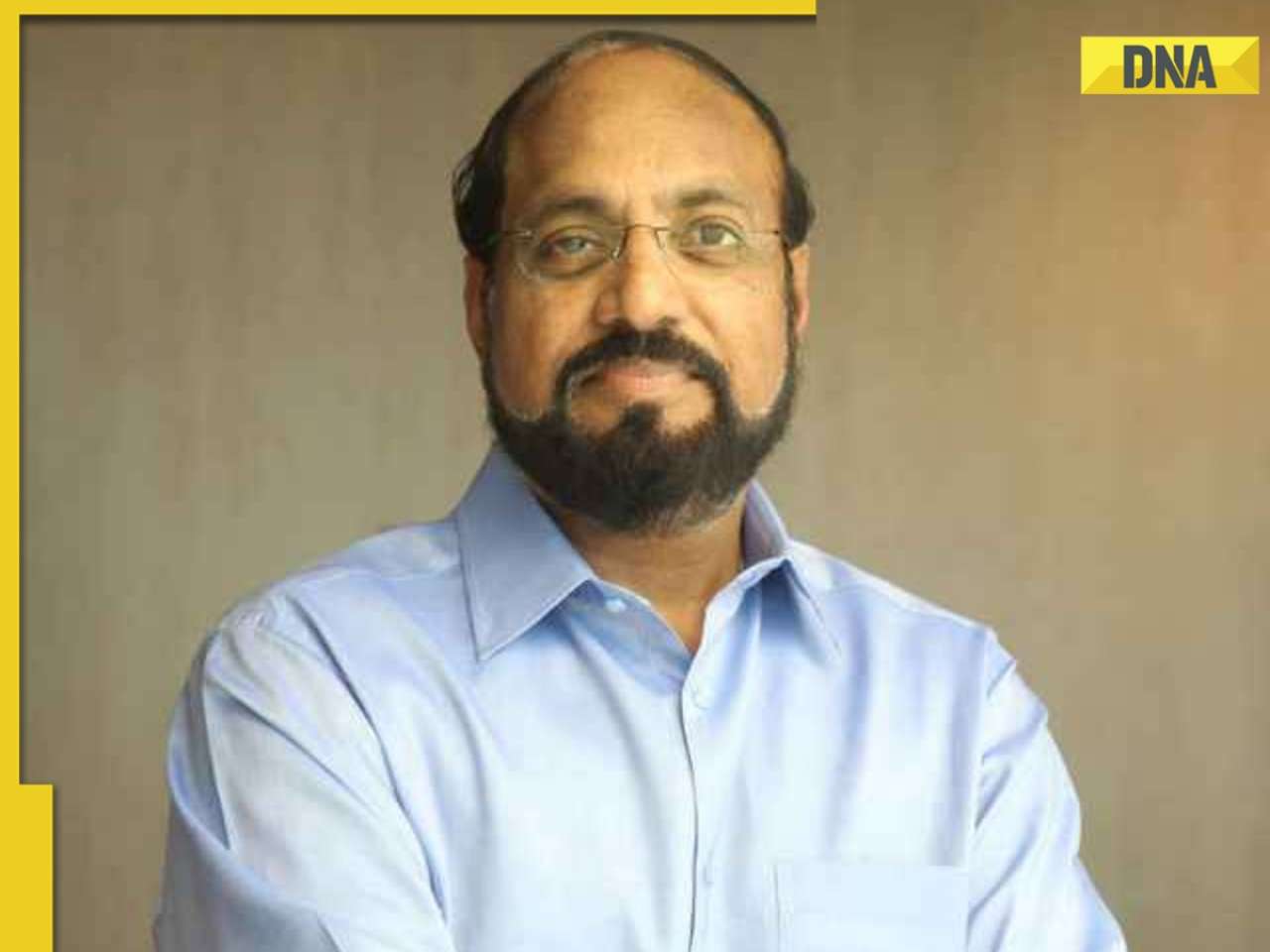

Dr Ajay G Karmarkar, scientist at IWST, said a team of three scientists at the institute is working on creating a material that mimics all the qualities of plastic but is biodegradable in nature.

“It is a composite of polylactic acid and nanocellulose. Polylactic acid is compatible with man-made polymers, hence can be used instead of plastic,” explained Karmarkar. The Rs32-lakh research project is funded by National Mission on Bamboo Applications, an initiative sponsored by the Department of Science and Technology (DST).

“The composite will not only reduce the burden on the environment, but will help in eliminating plastic,” Karmarkar said.

But it is not just about saving the planet, according to him, it is also about making a better quality product which can serve as an effective alternative to plastic. “The weight of the component can be reduced but it’s sturdier than plastic,” he said. However, he noted that some of the logistics have yet to be worked out. “We have already made nanocellulose in the lab, but getting polylactic acid from India has not been possible. So, we are importing it from America,” he said.

The biodegradable plastic developed by IWST would take a while to reach the industry. “We have just started working on the project; it will be commercially available in two years,” he said. “Companies should utilise IWST’s capabilities,” he said, adding that: “We obviously can’t give away our formulas and products for free; then it loses its value. We offer our services at a nominal price, but companies should utilise us properly.”

Karmarkar is hopeful that the product will be popular among the populace. “The material’s cost efficiency will make it easily accessible to the masses. Nanocellulose is much cheaper than other re-enforcement products like nanocarbon tubes, which costs a few thousand rupees per gram,” he said.

“Nanotechnology is the future of science,” he said. “Right now nanotechnology is being developed for everything, from drug application to material engineering, but we must be wary of the safety issues that it poses,” he added.

![submenu-img]() Maa Kali teaser: Raima Sen, Abhishek Singh film narrates 'horrifying' Direct Action Day during British Raj Bengal

Maa Kali teaser: Raima Sen, Abhishek Singh film narrates 'horrifying' Direct Action Day during British Raj Bengal ![submenu-img]() Watch: Rohit Sharma, Virat Kohli lift T20 World Cup trophy together during Team India's victory parade in Mumbai

Watch: Rohit Sharma, Virat Kohli lift T20 World Cup trophy together during Team India's victory parade in Mumbai![submenu-img]() Meet Indian genius, who worked on NASA's Rs 73700 crore project, married to a scientist, she is...

Meet Indian genius, who worked on NASA's Rs 73700 crore project, married to a scientist, she is...![submenu-img]() Watch: Fan climbs tree to watch Team India's victory parade up close, video goes viral

Watch: Fan climbs tree to watch Team India's victory parade up close, video goes viral![submenu-img]() Hathras stampede: Congress MP Rahul Gandhi to meet victims of incident tomorrow

Hathras stampede: Congress MP Rahul Gandhi to meet victims of incident tomorrow![submenu-img]() Meet Indian genius, who worked on NASA's Rs 73700 crore project, married to a scientist, she is...

Meet Indian genius, who worked on NASA's Rs 73700 crore project, married to a scientist, she is...![submenu-img]() Meet woman, civil servant for 30 years, now becomes first female chief secretary of...

Meet woman, civil servant for 30 years, now becomes first female chief secretary of...![submenu-img]() Meet Indian genius, a celebrated physicist, who was denied Nobel Prize in 2005, converted to Hinduism because..

Meet Indian genius, a celebrated physicist, who was denied Nobel Prize in 2005, converted to Hinduism because..![submenu-img]() Meet Indian genius who passed classes 8-12 in 9 months, became one of India's youngest engineer at 15, joined IIT for...

Meet Indian genius who passed classes 8-12 in 9 months, became one of India's youngest engineer at 15, joined IIT for...![submenu-img]() Meet Indian genius, who began career as assistant, later led key NASA mission, works as...

Meet Indian genius, who began career as assistant, later led key NASA mission, works as...![submenu-img]() Godman Bhole Baba's Lawyers Deny ‘Charan Raj’ Claim, Says Anti-Social Elements Behind Stampede

Godman Bhole Baba's Lawyers Deny ‘Charan Raj’ Claim, Says Anti-Social Elements Behind Stampede![submenu-img]() Meet Rishi Shah, The Indian-American Sentenced To 7.5 Years In Prison For $1 Billion Fraud Scheme

Meet Rishi Shah, The Indian-American Sentenced To 7.5 Years In Prison For $1 Billion Fraud Scheme![submenu-img]() Severe Turbulence On Spanish Flight Injures 30, Video Of Man Thrown Into Overhead Bin Goes Viral

Severe Turbulence On Spanish Flight Injures 30, Video Of Man Thrown Into Overhead Bin Goes Viral![submenu-img]() Haryana: Goods Train To Amritsar Derailed In Karnal, Containers Fall Off, Rail Traffic Disrupted

Haryana: Goods Train To Amritsar Derailed In Karnal, Containers Fall Off, Rail Traffic Disrupted![submenu-img]() 'Played With Religious Sentiments': Chirag Paswan Slams Rahul Gandhi Over His Remarks In Parliament

'Played With Religious Sentiments': Chirag Paswan Slams Rahul Gandhi Over His Remarks In Parliament![submenu-img]() DNA Verified: Did Kangana Ranaut party with gangster Abu Salem? Actress reveals who's with her in viral photo

DNA Verified: Did Kangana Ranaut party with gangster Abu Salem? Actress reveals who's with her in viral photo![submenu-img]() DNA Verified: New Delhi Railway Station to be closed for 4 years? Know the truth here

DNA Verified: New Delhi Railway Station to be closed for 4 years? Know the truth here![submenu-img]() DNA Verified: Did RSS chief Mohan Bhagwat praise Congress during Lok Sabha Elections 2024? Know the truth here

DNA Verified: Did RSS chief Mohan Bhagwat praise Congress during Lok Sabha Elections 2024? Know the truth here![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() 5 warm moments Ranveer Singh shared with fans that show why he is their favourite

5 warm moments Ranveer Singh shared with fans that show why he is their favourite![submenu-img]() In pics: Richa Chadha cheers for Ali Fazal, Isha Talwar, Vijay Varma, Shweta Tripathi pose at Mirzapur 3 screening

In pics: Richa Chadha cheers for Ali Fazal, Isha Talwar, Vijay Varma, Shweta Tripathi pose at Mirzapur 3 screening![submenu-img]() Meet Mickey Dhamejani, Jr Hrithik Roshan from Krrish, former child actor who quit films, is now...

Meet Mickey Dhamejani, Jr Hrithik Roshan from Krrish, former child actor who quit films, is now...![submenu-img]() In pics: India beat South Africa by 7 runs to lift second T20 World Cup title

In pics: India beat South Africa by 7 runs to lift second T20 World Cup title![submenu-img]() Alia Bhatt mesmerises in gown, Ranbir Kapoor looks classy in tuxedo in latest romantic photos, fans say 'couple goals'

Alia Bhatt mesmerises in gown, Ranbir Kapoor looks classy in tuxedo in latest romantic photos, fans say 'couple goals'![submenu-img]() Hathras stampede: Congress MP Rahul Gandhi to meet victims of incident tomorrow

Hathras stampede: Congress MP Rahul Gandhi to meet victims of incident tomorrow![submenu-img]() Hathras stampede: Six sevadars including two women arrested by UP police, key accused still on run

Hathras stampede: Six sevadars including two women arrested by UP police, key accused still on run![submenu-img]() CST Advanced Systems revolutionizes tactical Operations

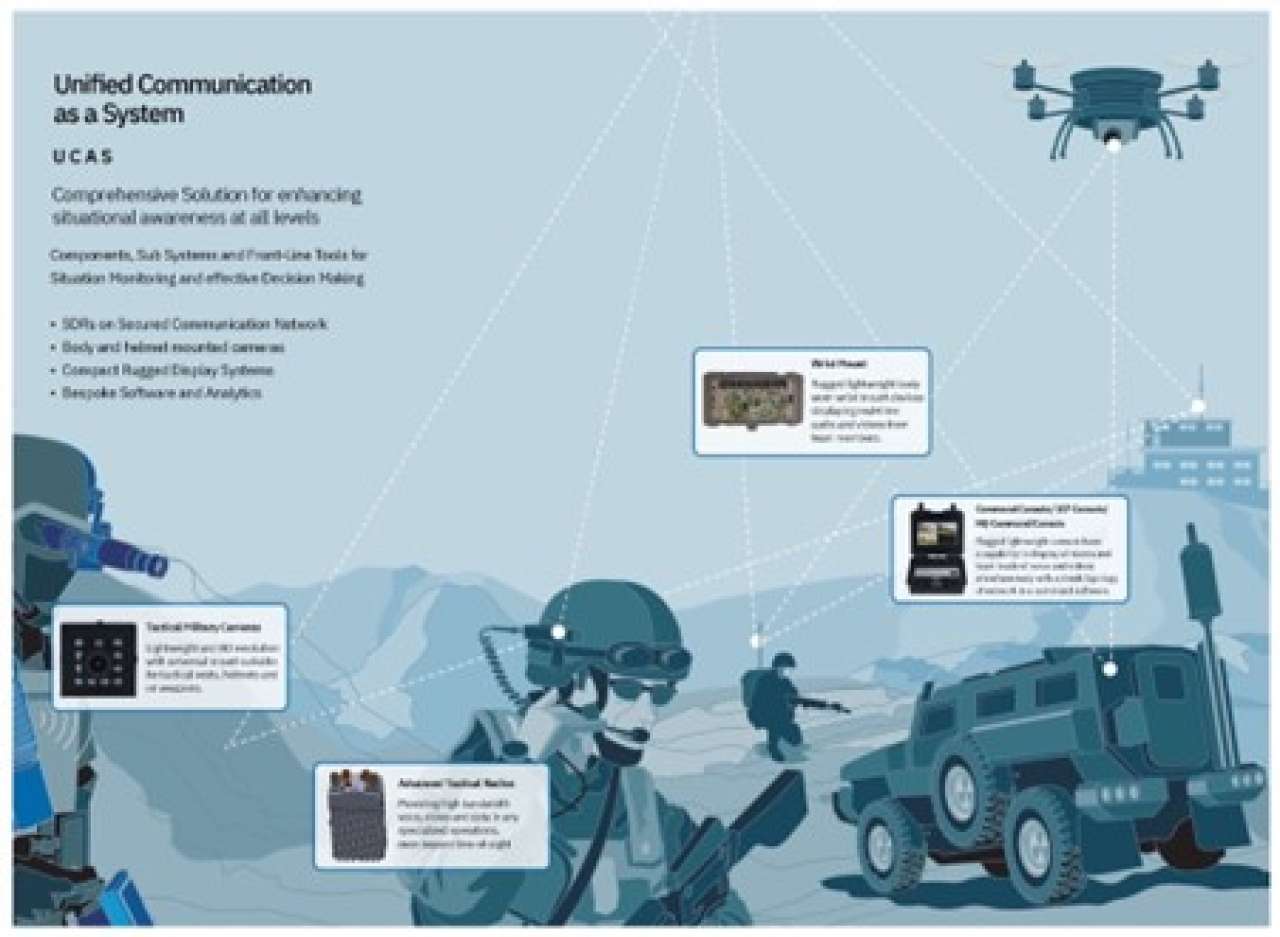

CST Advanced Systems revolutionizes tactical Operations![submenu-img]() 'We would all be...: ISRO chief issues eerie warning for humans and it's related to..

'We would all be...: ISRO chief issues eerie warning for humans and it's related to..![submenu-img]() This Pakistani leader was LK Advani's good friend, they both used to share letters in...

This Pakistani leader was LK Advani's good friend, they both used to share letters in...![submenu-img]() Lok Sabha Speaker's Election: What does the Constitution say?

Lok Sabha Speaker's Election: What does the Constitution say?![submenu-img]() Explained: Why is Kerala demanding to change its name to Keralam?

Explained: Why is Kerala demanding to change its name to Keralam?![submenu-img]() DNA Explainer: What is Kafala system that is prevalent in gulf countries? Why is it considered extremely brutal?

DNA Explainer: What is Kafala system that is prevalent in gulf countries? Why is it considered extremely brutal? ![submenu-img]() Lok Sabha Elections 2024: What are exit polls? When and how are they conducted?

Lok Sabha Elections 2024: What are exit polls? When and how are they conducted?![submenu-img]() DNA Explainer: Why was Iranian president Ebrahim Raisi seen as possible successor to Ayatollah Khamenei?

DNA Explainer: Why was Iranian president Ebrahim Raisi seen as possible successor to Ayatollah Khamenei?![submenu-img]() Maa Kali teaser: Raima Sen, Abhishek Singh film narrates 'horrifying' Direct Action Day during British Raj Bengal

Maa Kali teaser: Raima Sen, Abhishek Singh film narrates 'horrifying' Direct Action Day during British Raj Bengal ![submenu-img]() Kalki 2898 AD director Nag Ashwin reacts to audience reaction, reveals major details about Part Two: 'We shot about...'

Kalki 2898 AD director Nag Ashwin reacts to audience reaction, reveals major details about Part Two: 'We shot about...'![submenu-img]() This TV star to join Bigg Boss OTT 3 as wild card entry; it's not Shehzada Dhami, Bristi Samaddar, Rakhi Sawant

This TV star to join Bigg Boss OTT 3 as wild card entry; it's not Shehzada Dhami, Bristi Samaddar, Rakhi Sawant![submenu-img]() Auron Mein Kahan Dum Tha getting postponed is 'tough but good decision', exhibitors say 'we all know Munjya, Kalki...'

Auron Mein Kahan Dum Tha getting postponed is 'tough but good decision', exhibitors say 'we all know Munjya, Kalki...'![submenu-img]() Tahira Kashyap says husband Ayushmann Khurrana 'was not happy' with her books: 'He considers it blasphemous' | Exclusive

Tahira Kashyap says husband Ayushmann Khurrana 'was not happy' with her books: 'He considers it blasphemous' | Exclusive![submenu-img]() Mukesh Ambani's bahu Radhika Merchant dazzles in Durga shloka-inscribed lehenga for her 'mameru' ceremony, pics go viral

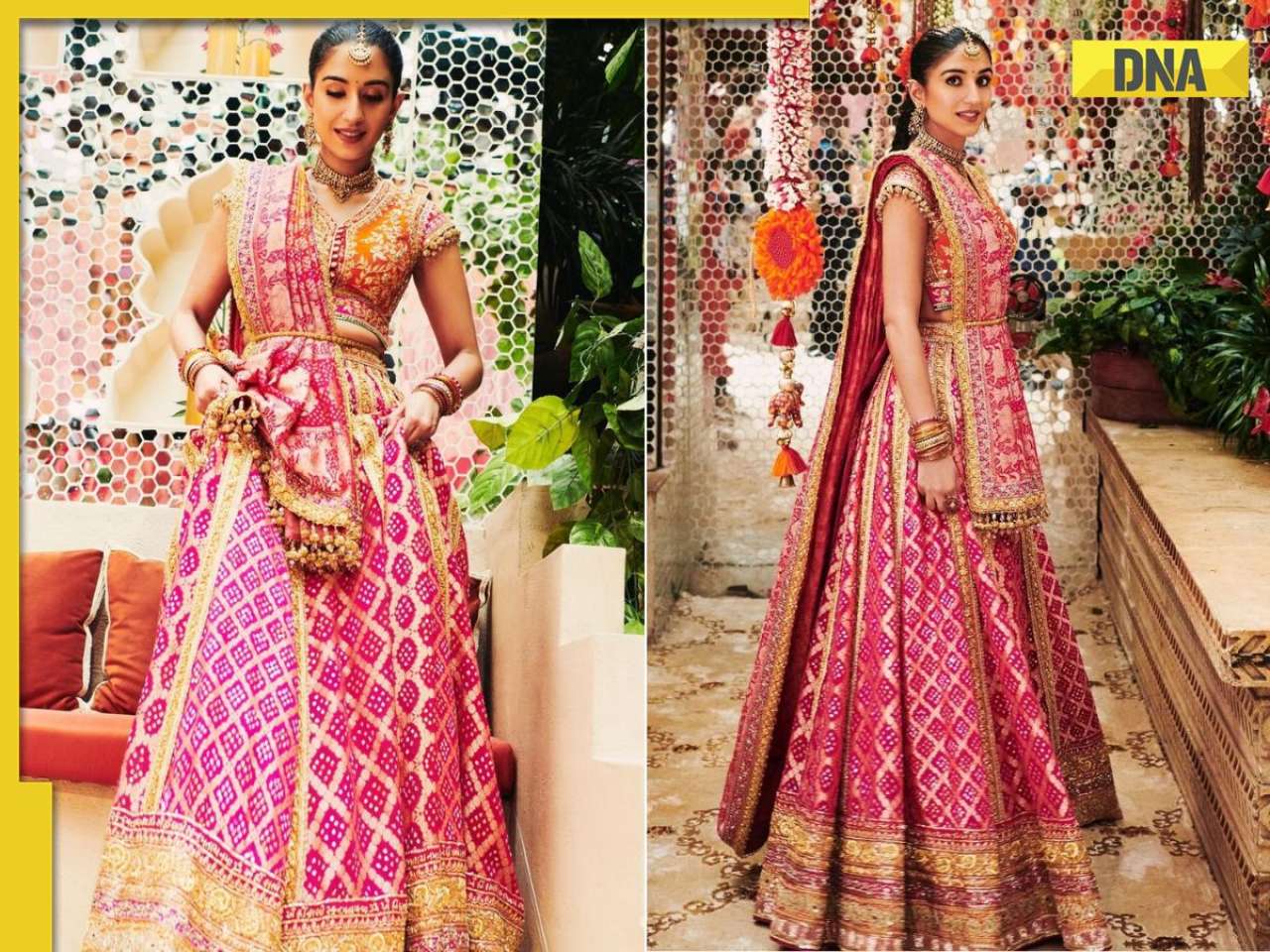

Mukesh Ambani's bahu Radhika Merchant dazzles in Durga shloka-inscribed lehenga for her 'mameru' ceremony, pics go viral![submenu-img]() Virat Kohli meets brother Vikas, family at Delhi hotel after returning from Barbados, see pics

Virat Kohli meets brother Vikas, family at Delhi hotel after returning from Barbados, see pics![submenu-img]() Viral video: AIIMS doctor grooves to ‘Tip Tip Barsa Paani’, sets internet on fire; watch

Viral video: AIIMS doctor grooves to ‘Tip Tip Barsa Paani’, sets internet on fire; watch![submenu-img]() Inside details of functions organised by Mukesh Ambani, Nita Ambani for Anant Ambani, Radhika Merchant's grand wedding

Inside details of functions organised by Mukesh Ambani, Nita Ambani for Anant Ambani, Radhika Merchant's grand wedding![submenu-img]() Mukesh Ambani, Nita Ambani's daughter Isha Ambani owns diamonds worth crores but her most prized jewellery is..

Mukesh Ambani, Nita Ambani's daughter Isha Ambani owns diamonds worth crores but her most prized jewellery is..

)

)

)

)

)

)